ABRA FLUID AG - Control of a cold isostatic press for tungsten carbide powders

The control of a cold isostatic press for pressing tungsten carbide powders should allow product-dependent multi-segment time pressure curves with controlled pressure raise and reduction up to 4000 bar.

The goal was to keep the operation for the complex process as simple as possible. ABRA FLUID AG placed great emphasis on process quality, monitoring and safety. The challenge with this application was the precise regulation of the extremely high pressures.

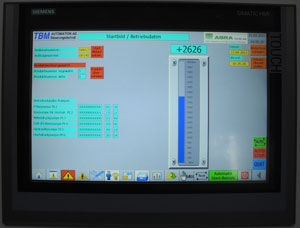

The control is based on SIMATIC S7-300 PLC with a 314C-2 PN / DP CPU and decentralized ET200S stations. The hydraulic controller is connected via Profibus to the PLC, which ensures a continuous monitoring. A SIMATIC TP1500 Comfort Touch Panel with 15" was used as HMI and connected via ProfiNet to the PLC control.

TBM Automation AG was able to bring its expertise in control technology to the solution. Siemens was the first choice for the customer due to the long-term availability and wide range of components.

The customer benefits from a high process quality and flexibility of the equipment. The HMI design of the product administration, the user interfaces and the parameterization allows easy operation, diagnosis and product change. Due to the long-term availability of the SIMATIC components, the investment is safe for many years.