Quality and performance - With vision systems for the brick industry

Over recent years, the trend within the brick industry has been that more and more highly automated systems are run by fewer and fewer operators. Consideration of employee costs, which shows that night shifts and weekend operations are the most expensive times, has meant owners need to consider the amount of staff required and thus has resulted in using more highly and advanced automated systems.

Now, what if a quality problem occurs and the operator is busy with another piece of equipment? We all know the scenario: Everything works as it should, until the operator is busy with something else! The die of the extruder tamps and ribs of the product is missing. But until someone actually notices the problem, second quality products or at worst, waste is produced for a very long time. As a result there is production downtime and unplanned costs. But what can we do to avoid this?

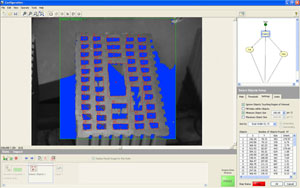

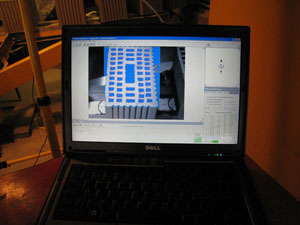

The answer to this problem is provided by intelligent vision systems. These are industrial cameras with integrated high-performance image processors to recognize differences in quality immediately and react accordingly. In response to this need TBM Automation AG has developed a vision application, which can be integrated into your equipment within seconds - for example, into your Freymatic cutting machine.

An electrical outlet and the connection of the monitoring signal into the release for the extruder clutch is enough to achieve this. If you have higher demands, then we cansimply integrate the monitoring into your control system.

The possibilities are almost unlimited. Depending on the mounting of the camera different dimensions, missing or incorrect contours, and other surface defects can be detected within milliseconds. With TBM's vision system correction of movements and handling positions is possible!

The best thing is that the vision system can also be set according to fault-tolerance. At TBM we know that the manufacturing of bricks and roof-tiles can sometimes be a "fuzzy science". Even when a product changes intervention by the operatoris unnecessary because the system is able to identify which product you have just fabricated and automatically chooses the relevant quality characteristics.

Is the vision system worth it? Is it not too expensive? - If loss in production and profit is compared to the cost of purchasing a TBM vision system, then the system pays foritself in no time at all!

Interested? Ask us! We at TBM would be pleased to provide more information or answer any questions you may have.